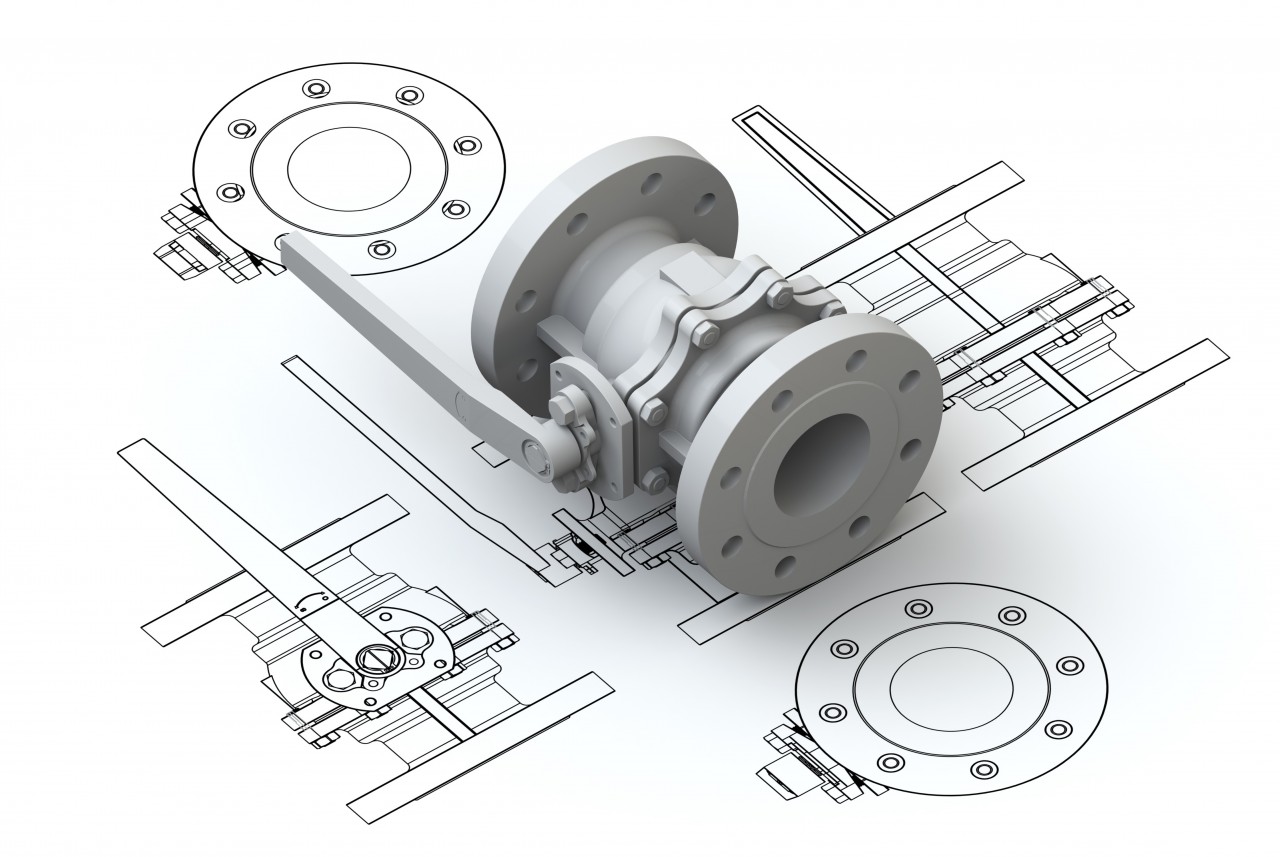

Prototyping

Today prototyping typically means layer based or additive manufacture. Having pioneered both Stereolithography and Selective Laser Sintering in the UK we are the specialists. Moreover, we offer a full range of machining options for functional plastic and metal prototypes, providing the most appropriate process to meet your timescales, quantities and functional requirements.

Form & Fit

“Form and fit” is all about validating the CAD data in a new design. It is about building the first set of prototypes that are dimensionally correct to permit the assembly of both mechanical and electrical components.

Depending on the project these prototypes also allow for assembly checks, i.e. can the parts be assembled and disassembled as the designer envisages, and is there sufficient access to mounting screws both on assembly and during routine maintenance?

The prototypes do not have to fulfill any mechanical requirements and process selection is made on the grounds of accuracy.

If you need professional experienced advice for your prototype, please get in touch.

Function

As additive manufacture (3D Printing) has developed, so the material properties have advanced significantly. Consequently many prototypes can validate functional requirements as well as “Form and Fit”.

Protobroker work with the full range of additive technologies, CNC Machining, Casting and Injection Moulding to ensure that prototypes are produced to the desired level to allow a full level of functional testing.

If higher quantities are required we also offer a full range of tooling options.

If this is what you are looking for, please get in touch.

Exhibition Models

Launching a new product at an exhibition can be nerve racking and very stressful.

Don't worry, Protobroker are here to help! With a successful track record of producing stunning models for exhibitions and product launches, against critical and often quite tight time lines, we can at least take one worry away!

We work to understand what you need, describe how we will achieve it, and then deliver that positive first impression that you have worked so hard for!

If this is what you are looking for, please get in touch.

Pre Production

In assessing the market response to a new design it is often essential to have ‘product’ available. Clearly at this stage production has not been signed off, so we are talking prototypes that look and feel the part.

Quantities can vary from one to several hundred, depending on the application, and invoke many different technologies to achieve the end result.

….and we all know how pre production can stretch into production!

Protobroker are specialists in low volume production with a variety of processes and options that may well surprise you; so if you are at the pre production stage in your project, please get in touch.